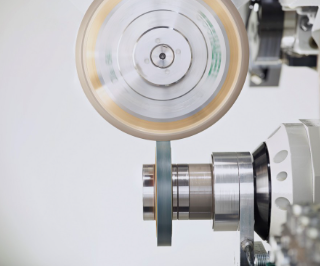

Maintaining equipment accuracy is vital in high-demand manufacturing settings at present. Ensuring the best performance and lifetime of grinding wheels used in manufacturing depends much on Industrial wheel truing devices. These machines modify the geometry and surface condition of wheels, hence improving their performance and lowering running downtime. They assist in keeping a constant cut rate, lower vibrations, and enhancing surface finish by means of removal of discrepancies and wear. These tools are getting more sophisticated as production changes, including high-precision sensors and flexible systems. Their relevance is growing, specifically in industries desiring precise accuracy, including aerospace, automotive, and heavy commercial.

Increasing Efficiency with Automated Wheel Truing Solutions

The growth of automated wheel truing solutions has changed how companies handle wheel maintenance. Unlike manual techniques, automated technologies lower human error, accelerate processes and offer consistent, high-quality outcomes. These options are perfect for high-volume businesses where consistency is very important. Smart integration features let them be synchronised with manufacturing lines, hence carrying out real-time diagnostics and modifications. This development increases general production by enabling operators to concentrate on other vital activities. From rail wheel maintenance to CNC machines, these systems are growing necessary. They show the way contemporary manufacturing moves toward automation, intelligence, and smooth operational flow.

Modern Manufacturing’s Integration of Truing Technologies

Modern manufacturing plants are adopting digital transformation; wheel truing is not an exception. Smarter and leaner operations are being driven by the incorporation of truing technologies into automated manufacturing lines. Modern truing devices use machine learning algorithms and IoT sensors that identify even the smallest abnormalities. These qualities guarantee that wheels are fixed before problems affect manufacturing by means of predictive maintenance. Cloud connectivity and real-time data gathering provide technicians with actionable information, hence enabling them to make educated choices. Wheel truing systems are also changing as factories become more networked; they are becoming important cogs in the machine of Industry 4.0 industrial settings.

Advanced Wheel Truing: Safety and Sustainability

Apart from output, innovative wheel truing technologies greatly enhance environmental sustainability and occupational safety. Worn or misaligned wheels can cause equipment failure, therefore creating safety concerns and raising maintenance costs. Accurate truing guarantees ideal wheel condition, hence decreasing wear on surrounding parts and minimising such hazards. Furthermore, it prolongs wheel life, therefore conserving resources and lowering the need for regular replacements. In particular, automated truing systems help environmentally responsible operations by using exact quantities of material and energy. Companies putting money into sustainable and safe training processes are also enhancing their brand and compliance credentials as regulatory criteria get more rigorous.

Wheel Truing Systems’ Cost-Effectiveness and ROI

Although the first cost of tyre truing systems especially automated ones—may appear significant, the long-term return on investment is remarkable. These technologies immediately support profitability by lowering scrap rates, enhancing product quality, and minimising machine downtime. Many businesses claim notable cost reductions in the first year of execution. The capacity to conduct training activities unattended or with little supervision also lowers labour expenses. From a tiny workshop to a big production factory, consistent wheel truing technology has clear economic advantages. For companies trying to remain competitive in tough industrial sectors, this is a wise decision.

Conclusion:

The need for precision maintenance tools cannot be emphasised as industrial settings get more complex. Leading the way towards more efficiency, safety, and sustainability are industrial wheel truing systems and automated wheel truing solutions. Their function in guaranteeing constant performance, waste reduction, and facilitating smart manufacturing lines is revolutionary. Investing in cutting-edge wheel-tracking technology is not only a decision but rather a need for businesses looking for future-proof solutions. Visit proemachinery.com to discover more about the newest inventions and locate the appropriate solutions that are fit for your company. The correct truing system starts your road to accuracy; the future of production is dependent on it.